According to a recent industry report, small businesses lose an average of $2,000 per vehicle annually due to inadequate fleet maintenance practices. This is a direct hit to your bottom line.

For small businesses operating fleets in Nigeria, the challenges are unique and often daunting. Our roads demand more from vehicles, and the operating environment can be unforgiving.

However, there’s a silver lining: implementing proper fleet maintenance strategies can reduce your operating costs by up to 30%.

Let’s explore the maintenance strategies that can keep your vehicles running efficiently and your business growing steadily.

1. Implement a Regular Maintenance Schedule

A well-structured maintenance schedule is the foundation of efficient fleet operations. Here’s how to create one that works:

- Utilize digital tools: Embrace fleet management software to set up automatic reminders and track maintenance tasks.

- Customize for each vehicle: Recognize that different vehicles have different needs based on age, model, and usage patterns.

- Maintain consistency: The most effective schedule is one that’s consistently followed.

Why is this crucial? Preventive maintenance typically costs 3-4 times less than reactive repairs. It’s about implementing proactive management that protects your investment.

2. Keep Detailed Maintenance Records

Your fleet’s maintenance history is a goldmine of information. Here’s how to leverage it effectively:

- Opt for digital records: Cloud-based systems offer accessibility and ease of analysis.

- Be comprehensive: Record all details including mileage, repairs, costs, and even minor issues reported by your drivers.

- Conduct regular analysis: Use these records to identify trends and make informed decisions about vehicle management.

Components of a Comprehensive Maintenance Record

Vehicle Details

Make, Model, Year, VIN

Service History

Dates, Services Performed

Issues & Repairs

Problems, Solutions, Costs

Performance Data

Mileage, Fuel Efficiency

A comprehensive maintenance record is your key to efficient fleet management.

Pro tip: Consider using Salcomms Trackers’ integrated maintenance logging system. It provides a centralized platform for all your maintenance data, enabling easier tracking and analysis.

3. Train Drivers in Basic Maintenance

Your drivers are on the front lines of fleet maintenance. Equip them with the knowledge to be your first line of defense:

- Provide basic maintenance training: Cover essential checks like fluid levels, tire pressure, and identifying unusual vehicle behavior.

- Implement a daily inspection routine: Create a straightforward checklist for drivers to complete before and after their routes.

- Encourage proactive reporting: Foster a culture where drivers feel empowered to report potential issues early.

Remember, a driver who understands the importance of vehicle care is an asset to your maintenance strategy and your business’s efficiency.

4. Prioritize Tire Maintenance

Tires are a critical component of vehicle performance and safety. Here’s how to ensure they’re always in top condition:

- Regular pressure checks: Implement weekly tire pressure checks. Underinflated tires can increase fuel consumption by up to 3%.

- Adhere to rotation schedules: Rotate tires every 5,000-8,000 km to ensure even wear and extend their lifespan.

- Monitor alignment: Check wheel alignment every 20,000 km. Proper alignment reduces tire wear and improves fuel efficiency.

| Maintenance Task | Frequency | Importance | Notes |

|---|---|---|---|

| Tire Pressure Check | Weekly | High | Adjust for load and road conditions. Proper inflation is crucial for rough roads. |

| Tire Rotation | Every 10,000 km | Medium | Ensures even wear, especially important for unpaved roads. |

| Wheel Alignment | Every 20,000 km or as needed | High | Critical for uneven road surfaces and pothole-heavy routes. |

| Tread Depth Check | Monthly | High | Replace tires when tread depth is below 3mm. Essential for traction on varied surfaces. |

| Visual Inspection | Daily | Medium | Check for cuts, bulges, or embedded objects. Nigerian roads can cause rapid tire damage. |

| Balancing | Every 20,000 km or when vibration is felt | Medium | Improves ride quality and extends tire life on rough roads. |

Did you know that proper tire maintenance could improve your fuel efficiency by up to 3%?

In the context of Nigeria’s fuel prices, this translates to significant operational savings.

Implementing these maintenance strategies will really help optimize your fleet’s performance.

With comprehensive fleet tracking and management tools, you can monitor these aspects more effectively, ensuring your vehicles are always in prime condition to serve your business needs.

5. Fluid Management: The Lifeblood of Your Fleet

Ignoring your fleet’s fluids is like ignoring a leaking roof—it’ll cost you big time. Here’s your fluid management cheat sheet:

- Oil: Change it religiously. Your engine’s life depends on it.

- Coolant: Check monthly. A blown head gasket costs more than your weekly revenue.

- Brake fluid: Inspect every 3 months. Because stopping is kind of important.

- Transmission fluid: Check quarterly. A new transmission costs more than some used vehicles.

| Fluid | Check Frequency | Replace Frequency |

|---|---|---|

| Engine Oil | Weekly | Every 5,000-7,500 km |

| Coolant | Monthly | Every 2 years or 30,000 km |

| Brake Fluid | Every 3 months | Every 2 years or as needed |

| Transmission Fluid | Quarterly | Every 60,000-100,000 km |

Pro tip: Use <a href=”https://www.salcommstrackers.com/vehicle-tracking“>Salcomms Trackers’ maintenance alerts</a> to never miss a fluid check again.

6. Leverage Technology: Your 24/7 Maintenance Assistant

Welcome to the 21st century, where your fleet can tell you what it needs before it breaks down. Here’s how to listen:

- Telematics systems: They’re not just for tracking. They’re your early warning system.

- Automated alerts: Set them up for everything from oil changes to brake pad replacements.

- Data analysis: Use it to predict failures before they happen.

Remember, technology is only as good as how you use it, so you have to make it your maintenance assistant.

7. Your Mechanic Is Your New Best Friend

Finding a good mechanic is like finding a good business partner. Here’s how to do it right:

- Ask for recommendations from other fleet owners

- Check online reviews, but take them with a grain of salt

- Start with small jobs to test their reliability

- Negotiate service contracts for better rates

- Build a relationship—a mechanic who knows your fleet is worth their weight in gold

8. Mobile Maintenance Brings The Shop To You

Time is money, and downtime is burning cash. Here’s how mobile maintenance comes to the rescue:

- Pros:

- Minimizes vehicle downtime

- Can be more cost-effective for small fleets

- Allows for maintenance during off-hours

- Cons:

- May be more expensive per service

- Limited in the types of repairs they can perform

Run the numbers to assess if it’s worth it. If it keeps your vehicles on the road more, then it’s probably a great idea.

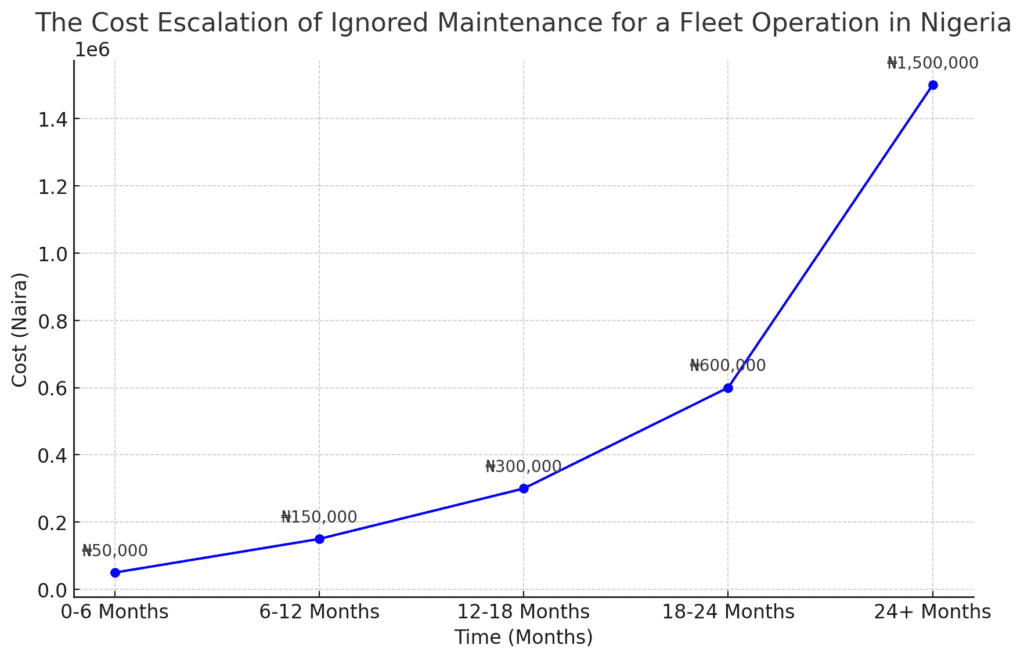

9. Small Issues Are Your Silent Profit Killers

That little rattle? It’s the sound of money leaking from your bank account. Here’s why small issues matter:

- A minor issue today = a major repair tomorrow

- Small fixes are cheaper and faster

- Addressing small issues improves overall vehicle performance

10. Vehicle Replacement: Planning for the Future

Every vehicle has a lifecycle, and knowing when to say goodbye can save you a fortune. Consider:

- Mileage: High mileage vehicles cost more to maintain

- Age: Older vehicles are less fuel-efficient and more prone to breakdowns

- Repair frequency: If you’re on a first-name basis with your mechanic, it might be time to upgrade

Use this simple formula:

If (Annual Maintenance Costs > 50% of Vehicle's Value), Consider Replacement11. Use Data As Your Secret Weapon

Data isn’t just for tech giants. It’s your fleet’s secret sauce. Here’s how to use it:

- Track everything: Miles driven, fuel consumption, maintenance costs

- Analyze regularly: Look for patterns and anomalies

- Act on insights: Use data to make informed decisions about maintenance, replacements, and driver training

Treat Your Fleet Like Your Profit Engine

Every well-maintained vehicle is a workhorse for your profits so when you take maintenance seriously, you’re actually driving your business forward.

Remember:

- Regular maintenance isn’t a cost—it’s an investment

- Your drivers are your first line of defense

- Technology is your ally—use it

- Data turns guesswork into strategy

Ready to turn your fleet into a lean, mean, profit-generating machine?